Security Innovation Technology for a Sustainable Future

Harnessing advanced technology and eco-friendly practices to create reliable, high-performance security solution.

Our Technology and Innovation

At MESHTECTM , we drive innovation across all areas of our business, from advanced security technology to sustainable production.

By embracing cutting-edge solutions and continuous improvement, we deliver reliable, high-performance products that exceed evolving customer needs.

By embracing cutting-edge solutions and continuous improvement, we deliver reliable, high-performance products that exceed evolving customer needs.

We leverage the latest advancements in automation and data-driven processes to enhance the precision and performance of our products.

• Smart manufacturing technologies drive operational excellence.

• By embracing digital transformation, we ensure that our production processes are streamlined, and our products meet the highest quality standards.

• Smart manufacturing technologies drive operational excellence.

• By embracing digital transformation, we ensure that our production processes are streamlined, and our products meet the highest quality standards.

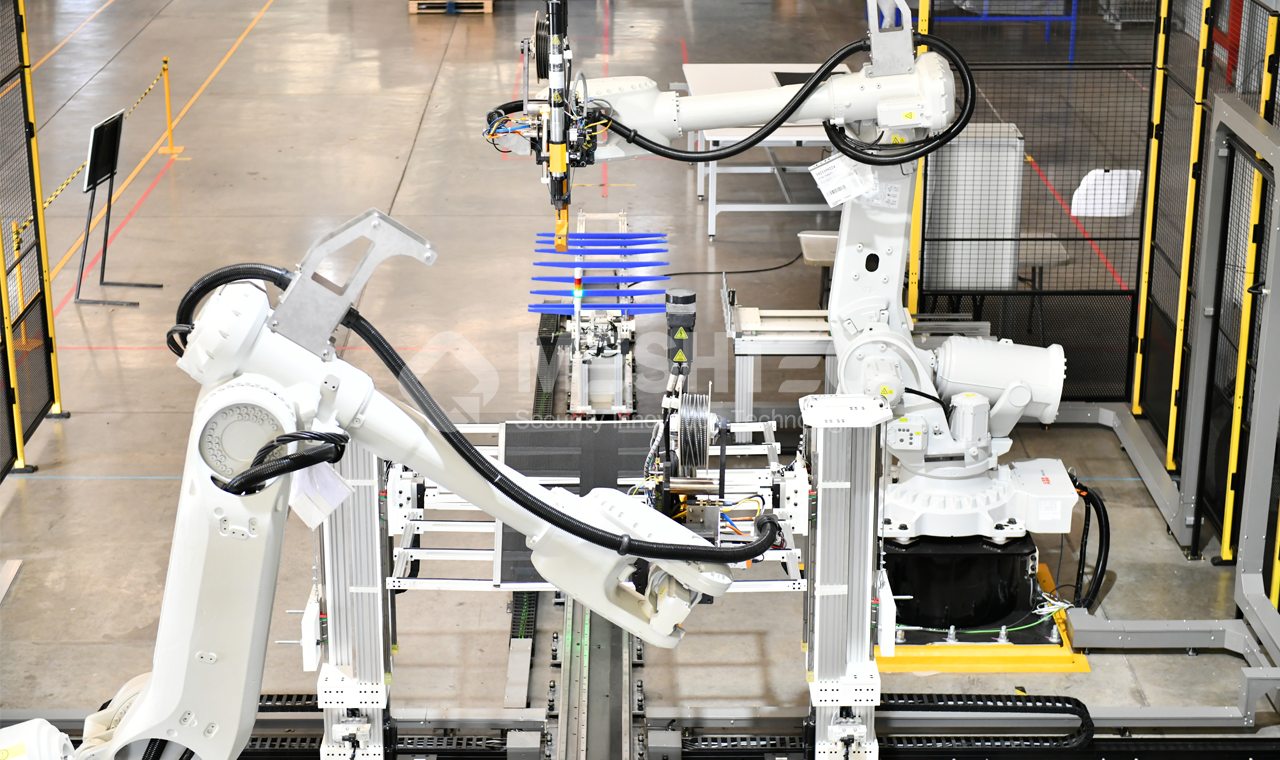

Manufacturing Innovation

Our state-of-the-art facilities are equipped with advanced machinery and automated systems to maintain precision and efficiency at every stage.

• Robotic arms handle complex assembly processes with accuracy.

• Lean manufacturing principles reduce waste and improve production speed.

• Real-time monitoring systems ensure consistent product quality.

• Lean manufacturing principles reduce waste and improve production speed.

• Real-time monitoring systems ensure consistent product quality.

This focus on manufacturing innovation allows us to increase productivity while maintaining the highest quality standards.

Product Innovation

Our in-house R&D team continually develops next-generation security solutions that combine strength, design, and functionality.

• Innovative materials enhance product durability and aesthetics.

• Custom design options allow seamless integration with diverse architectural styles.

• Enhanced performance features provide greater security without compromising visibility.

• Custom design options allow seamless integration with diverse architectural styles.

• Enhanced performance features provide greater security without compromising visibility.

Through continuous product innovation, we offer security solutions that are both effective and visually appealing.

Sustainability Innovation

We are committed to minimizing our environmental impact through responsible production and sustainable practices.

• Solar-powered facilities reduce carbon emissions.

• Recycling and waste reduction initiatives are integrated into our operations.

• A zero-food waste program transforms canteen waste into fertilizer.

• Recycling and waste reduction initiatives are integrated into our operations.

• A zero-food waste program transforms canteen waste into fertilizer.

Our approach to sustainability innovation reflects our dedication to protecting both people and the planet.